Successful Project Begins with a Precision RFQ

Effective communication and understanding your needs are key to crafting precise RFQs that lead to tailored solutions

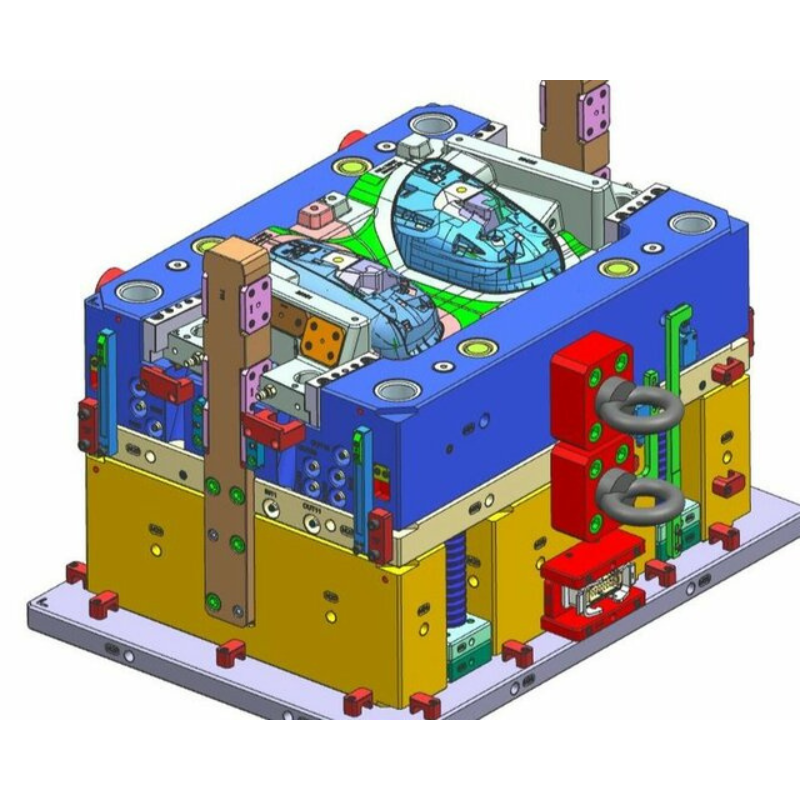

Communicating Mold Specs

Understanding Your Product’s Needs, Materials, and Production Goals for Accurate Quotes and Optimized Manufacturing Solutions

- Ensure the mold design aligns with the product’s functionality and end-use.

- Help choose the best material for the project.

- Tailor mold solutions based on production goals.

Design Feedback

We’ll analyze your parts for manufacturability, providing full visibility into cost drivers. if we identify any potential manufacturing risk, we’ll offer recommendations to mitigate them, ensuring a smooth production process.

- Receive expert feedback quickly after we review your design.

- Your design remains confidential-protected under our NDA.

- Get a detailed cost analysis with no obligation to purchase.

Quote

Fast lead times, competitive pricing, and exceptional service- all to meet the needs of project.

- You received a detailed quote within 24 hours

- Accept STEP, IGES, or STL formats for accurate assessments

- 2D file is acceptable

- Multiple lead time and delivery options to keep you on budget

FAQs

What information do I need to provide to receive an accurate mold quote?

To provide a precise quote, we require the following:

- 3D CAD files of your product (STEP or IGES format preferred)

- Material specifications for both mold and parts

- Expected production volume

- Surface finish requirements

Special features, such as inserts, overmolding, or hot runner systems This allows us to calculate costs based on mold complexity, materials, and expected lifetime.

What factors influence the cost of a mold?

Several factors affect the price:

- Mold size and complexity

- Type of steel or material used for the mold

- Number of cavities (single or multi-cavity)

- Special features like conformal cooling, side actions, or inserts

- Expected mold life (prototype vs. long-term production)

How long does it take to manufacture a mold after the order is placed?

Standard lead time for mold manufacturing is 2 to 4 weeks for less complex molds and 5 to 6 weeks for more intricate designs. We prioritize timely delivery without compromising on quality, and we will keep you updated on the progress throughout the process.

What payment terms do you offer for mold projects?

We typically require a 50% deposit to begin production, with the balance due upon sample approval or prior to mold shipment. However, we are flexible with terms based on the project size and client relationship.

How do you ensure mold quality and durability?

We use high-grade steel, advanced CNC machining, and EDM processes to manufacture molds. Each mold undergoes rigorous testing, including mold flow analysis, trial runs, and precision inspections, to ensure it meets both your specifications and industry standards.

Do you offer mold validation or sample production before final delivery?

Yes, we provide sample runs (typically 50 to 100 pieces) for you to validate the mold’s performance before it’s shipped. Any adjustments required will be made at this stage to ensure the mold is ready for full production once it arrives at your facility.