Innovating Mold Tooling for a Better Tomorrow

CENTERMOLD is dedicated to delivering high quality molds through a comprehensive and precisely controlled manufacturing process. Our commitment to quality and precision drives us to continuously refine our methods, ensuring we meet the diverse needs of our clients..

Material Procurement

Choosing the appropriate mold base according to the design requirements and specifications.

Selecting high-quality steel for the core and cavity to ensure durability and performance.

Sourcing essential mold components such as ejector pins, guide pins, bushings, and other standard parts.

Precision Tooling and Machining

Utilizing advanced CNC machines to achieve precise dimensions and tolerances.

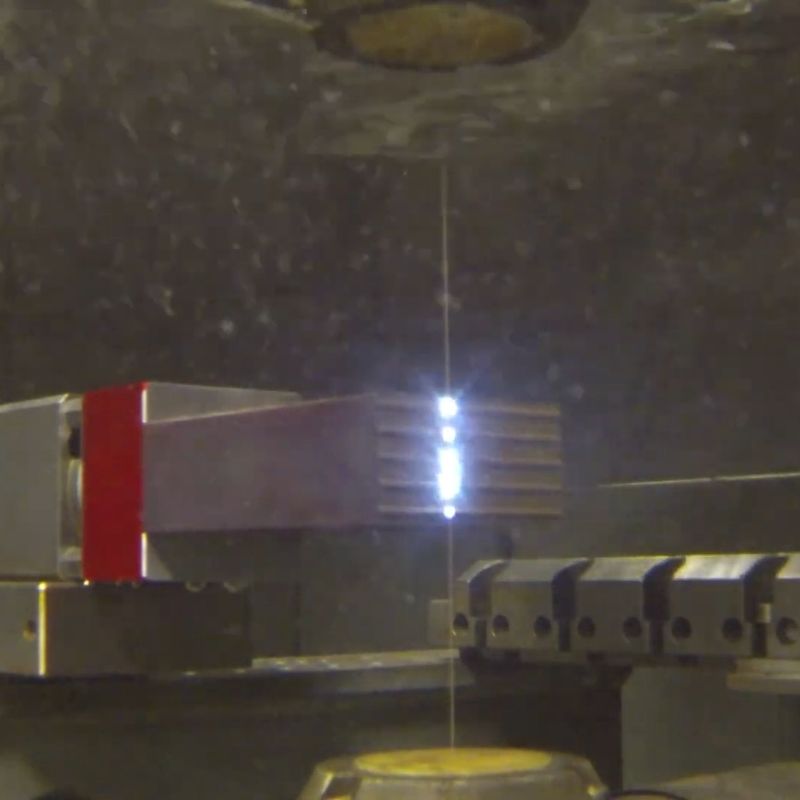

Sinker EDM: Creating complex shapes and fine details in mold components.

Wire EDM: Cutting intricate shapes.

Surface Grinding: Achieving precise flatness and smooth surfaces.

Polishing: Hand and machine polishing to achieve the required surface finish andtexture

Inspection: Verifying surface finish and dimensional accuracy through detailed inspection.

Heat Treatment and Surface finishing(optional)

Applying heat treatment processes to enhance the hardness and durability of mold steel.

Hardness Testing: Performing hardness tests to ensure the treated components meet the required specifications.

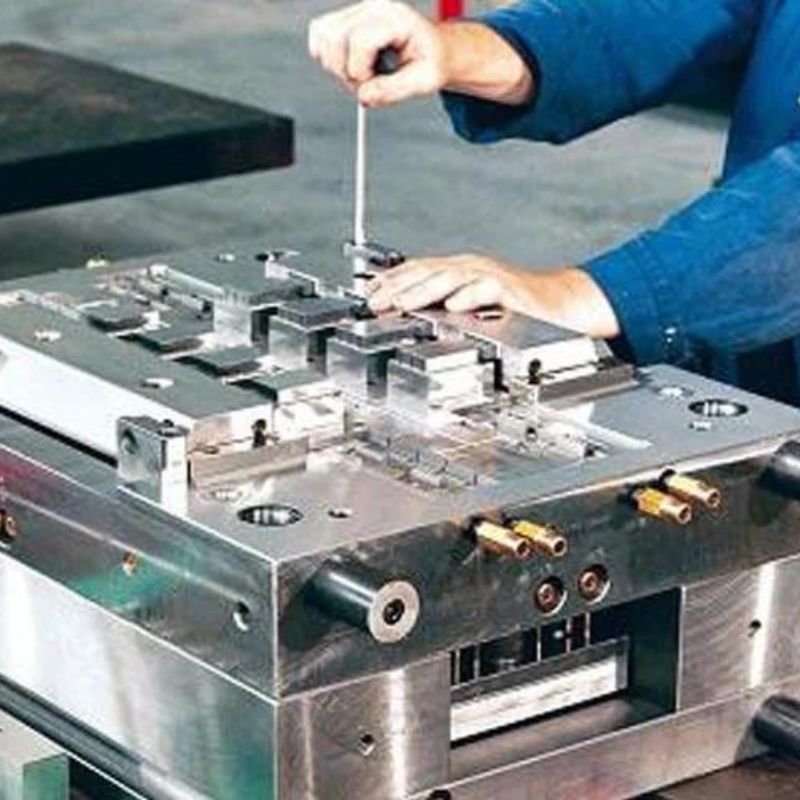

Fitting and Assemble

Assembling mold components and ensuring proper fit and function.

Performing any necessary final machining operations to ensure all parts fit together seamlessly.

Conducting dimensional inspections to verify all components meet design requirements.

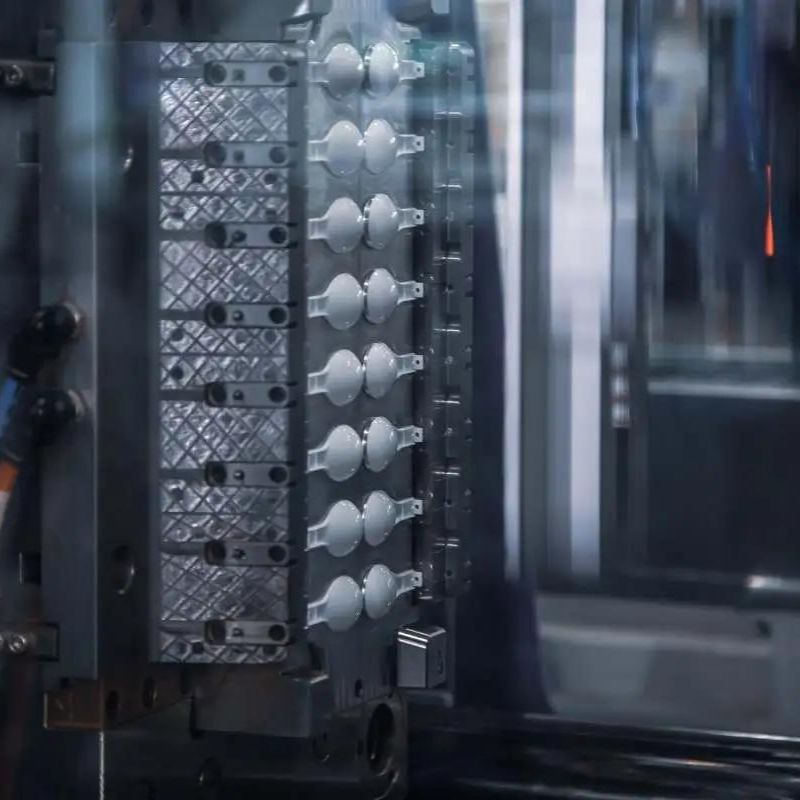

T0 Trial shot

Conducting trial runs to test the mold.

Assessing mold performance, identifying any issues, and making necessary adjustments.

Series of Work

Expertly crafted molds, combining advanced precision machining and rigorous trial runs for flawless production results.

Electrode Machining

Precision CNC

EDM

Wire Cut EDM

Polishing

Assembly

Trial Shot