Precision Metal Injection Molding (MIM)

Innovative MIM technology for manufacturing highly complex and precise metal components. Perfect for intricate designs requiring superior material performance.

Create high-performance metal components effortlessly

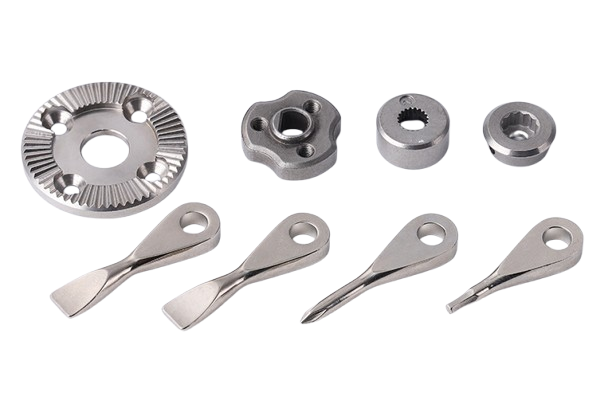

Precision MIM Metal Parts

Precision for Complex Designs

Combining the versatility of injection molding with the strength of metals, MIM delivers complex, high-strength parts with unmatched precision. Ideal for small to medium production runs, it’s the perfect solution for intricate components.

Key Benefits:

- High Design Freedom: Create complex geometries with thin walls and detailed features.

- Exceptional Strength and Durability: Achieve the mechanical properties of solid metals.

- Cost Efficiency: Perfect for small to medium production volumes, reducing secondary machining.

- Material Versatility: Wide range of materials, including stainless steel, titanium, and high-performance alloys.

MIM vs. CNC Machining

Metal Injection Molding (MIM) and CNC Machining each have unique strengths—understanding their differences helps you select the best solution for your project needs.

Comparison Highlights

- Complexity vs. Precision: MIM excels at producing intricate designs with minimal material waste, while CNC offers unparalleled precision for custom or tight-tolerance parts.

- Material Utilization: MIM uses metal powders efficiently for complex shapes, whereas CNC removes material from solid blocks, leading to higher scrap rates.

- Production Volume: MIM is cost-effective for small to medium batch runs, while CNC is ideal for low-volume prototypes or high-end, one-off parts.